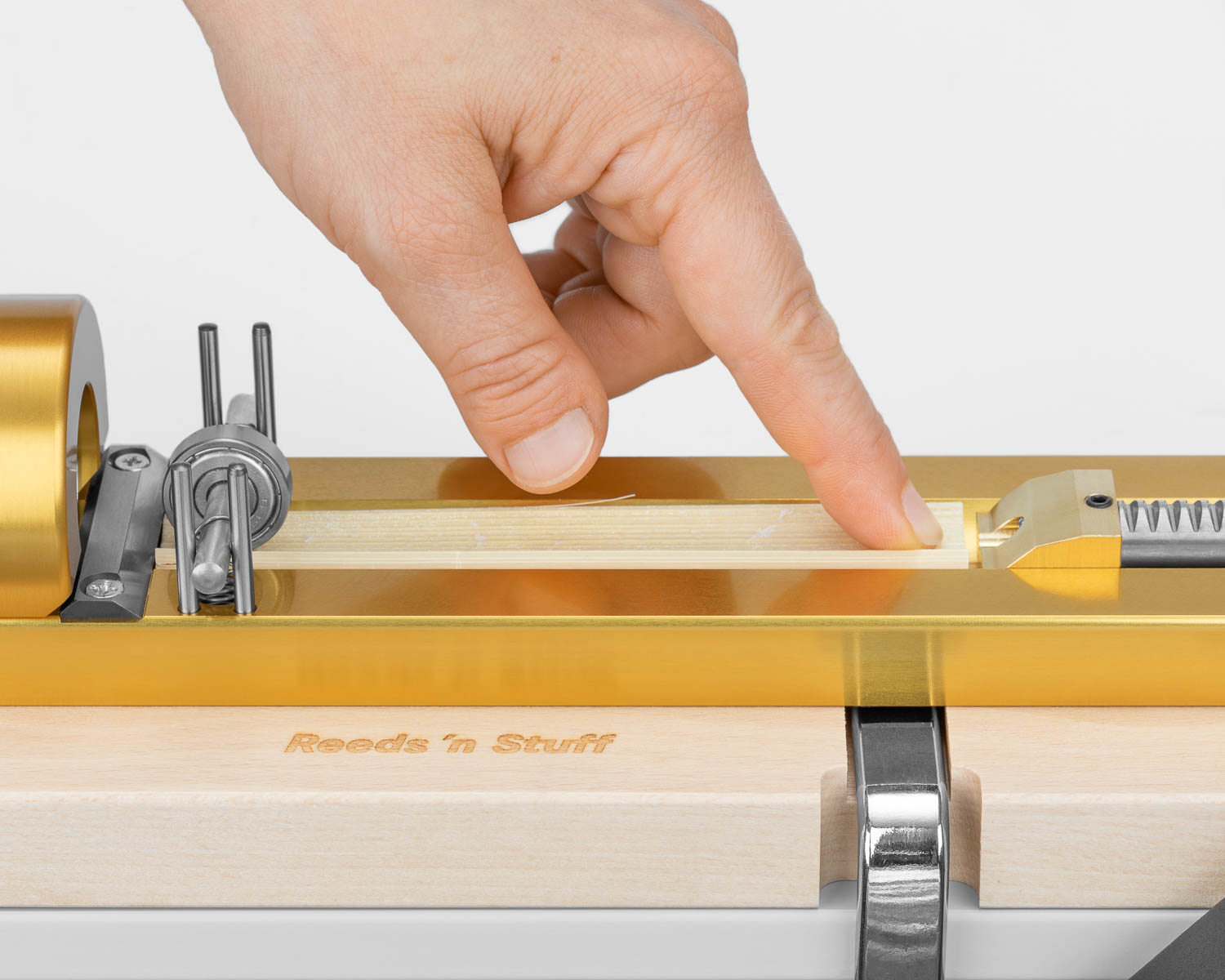

Figure Machine

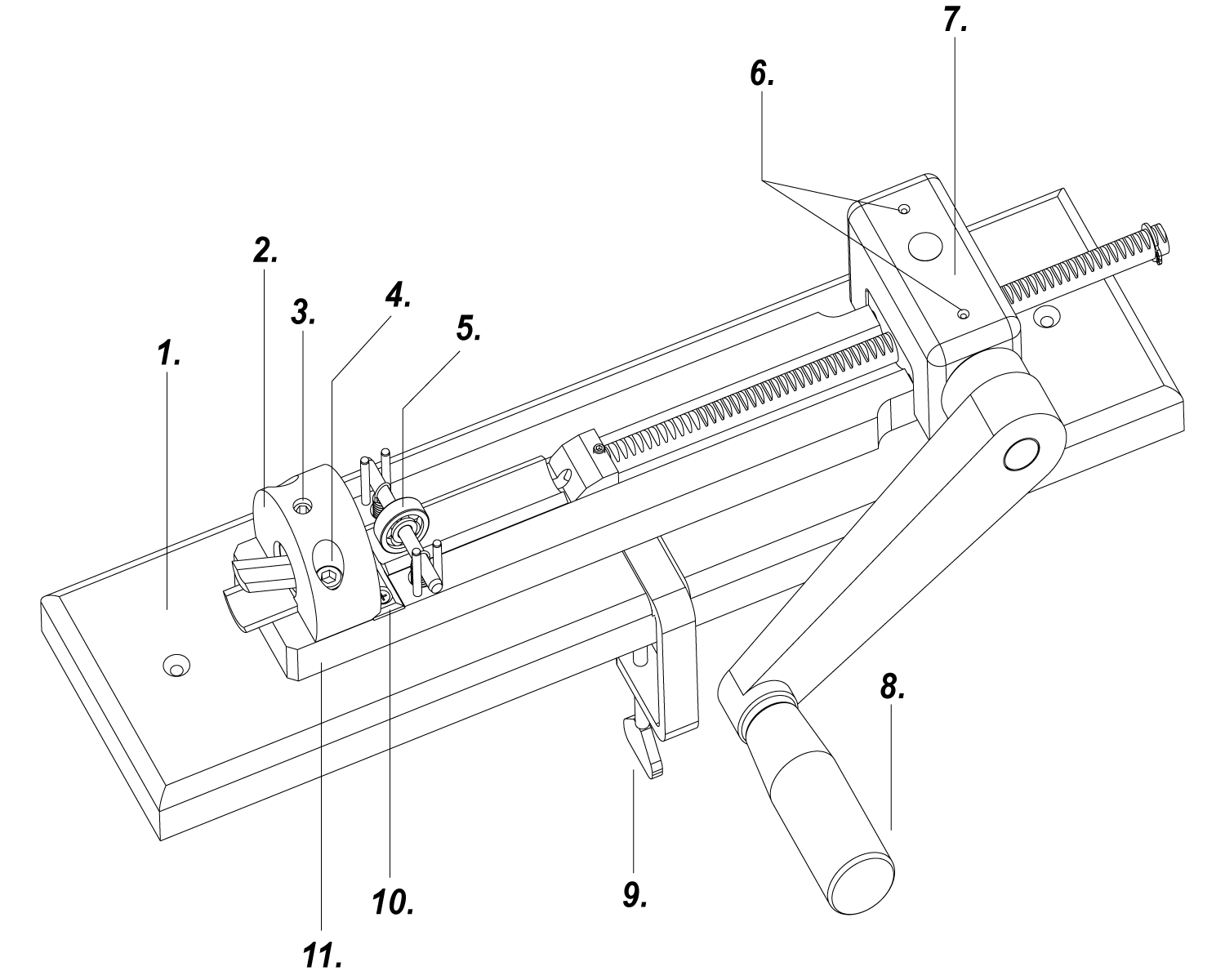

1.

Wooden base

2.

Holder for cylindrical blade

3.

Locking screw for cylindrical blade

4.

Screws for holder for cylindrical blade

5.

Roller for holding down the cane

6.

Oil holes

7.

Gearbox

8.

Crank

9.

Clamp

10.

Side Trim Blade

11.

Bed

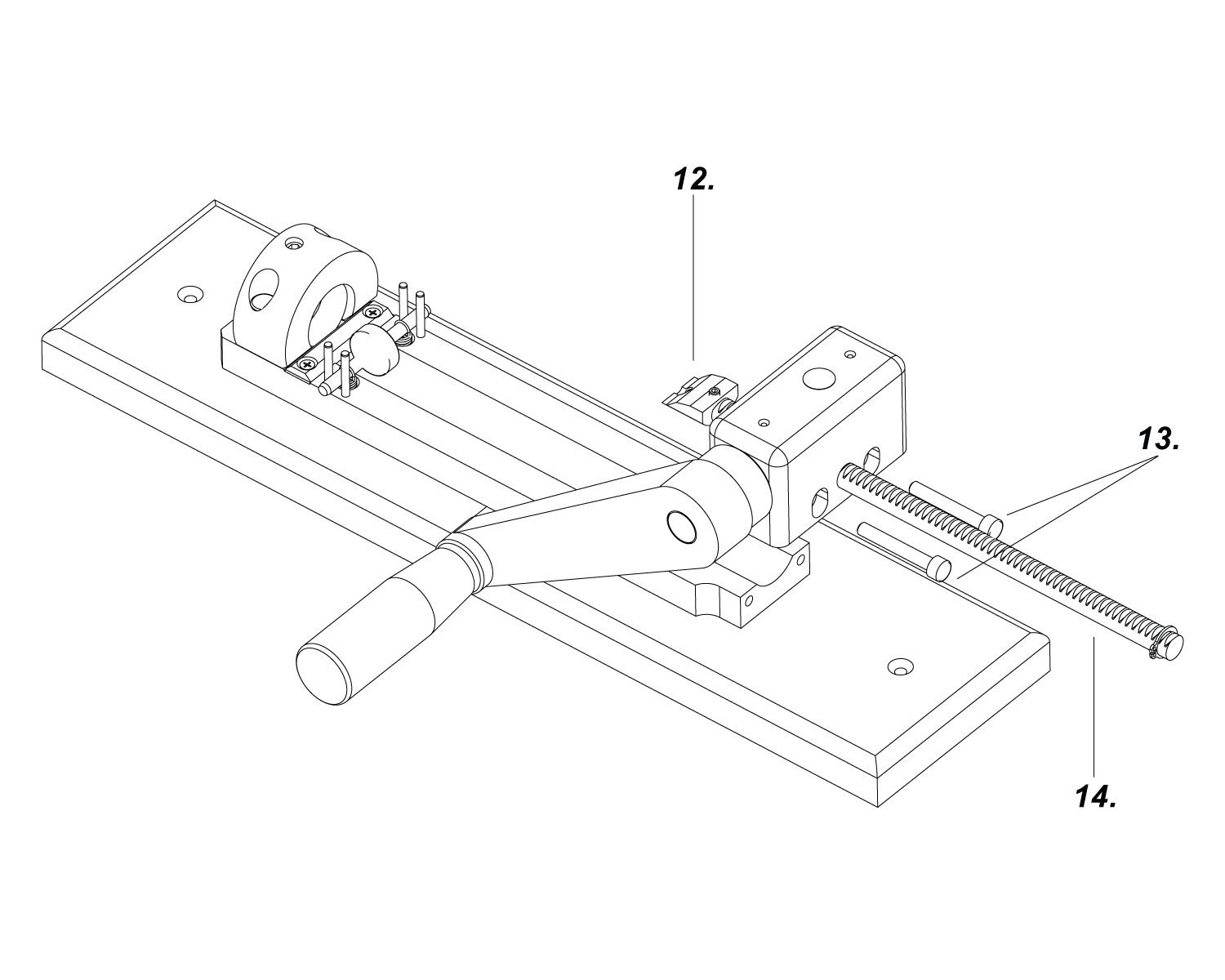

Figure Gear Box

12.

Pusher

13.

Screws for Gearbox

14.

Gear rack

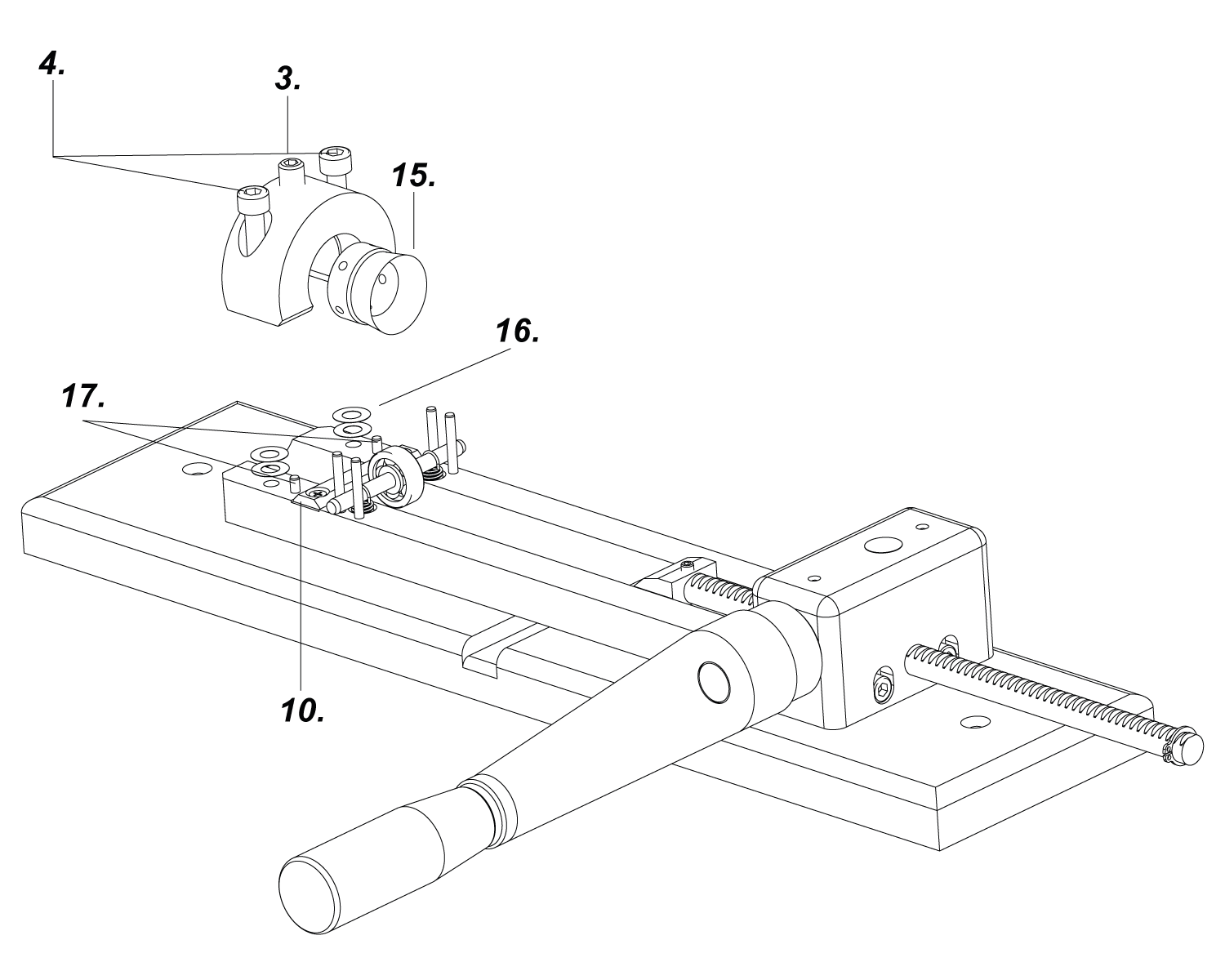

Figure Blade Unit

3.

Locking screw for round spare blade

4.

Screws for holder for round spare blade

10.

Side Trim Blade

15.

Round spare blade

16.

Shim rings

17.

Dowel pins

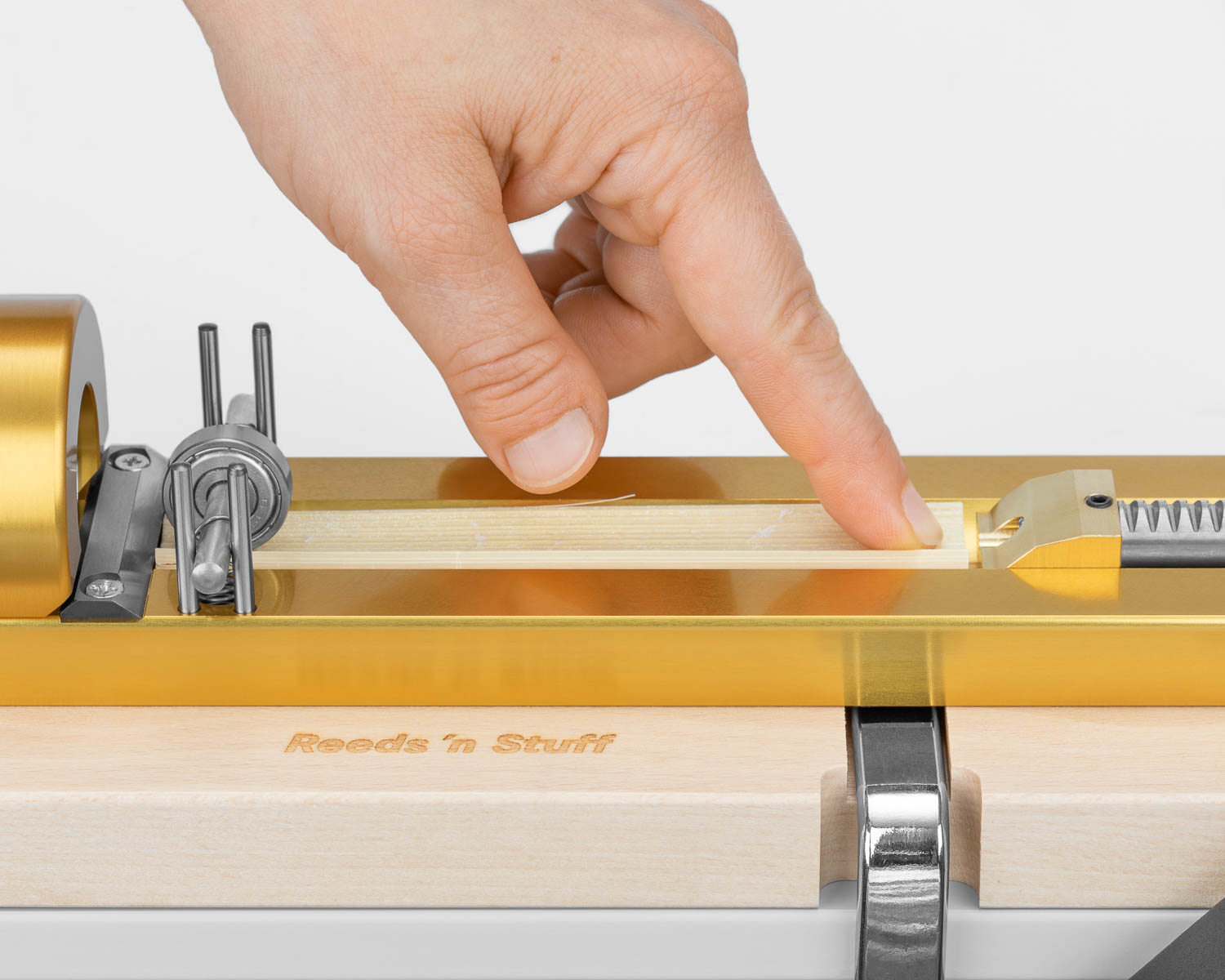

Gouging

Place the cane into the gouging bed of the machine. Press down, applying most of the pressure on the left end (near the blades) and turn the crank clockwise. This is very important in order to obtain good results. Otherwise, the results may be unpredictable. Once the cane is fully under the first blade, let up on the crank momentarily so you can push the other (right) end down fully into the bed, and then resume. (This last step may sound a bit unnecessary, but plenty of good looking cane isn’t as perfectly flat as we imagine it to be.)

Continue turning the crank until the pushrod reaches its limit. Then reverse the crank and load the next piece, which will eject the first one, and repeat the above process. Please do not try to pull out the last piece due to risk of injury. Instead, push the last piece out with a pregouged piece of cane.

Changing the Gouging Thickness

We recommend a thickness of the pregouged cane not less than the following:

Bassoon: 1,70 mm

Contra Bassoon: 2,00 mm

Remove the screws for the round blade holder and then loosen the blade-fixing screw.

Adding or removing washers will result in the following changes to thickness:

add washers = thicker gouging

remove washers = thinner gouging

(Important: be sure to use an equal number of washers on both sides!)

Place the round blade holder with the blade inserted back onto the pins, fasten the screws for the round blade holder, and then tighten the blade-fixing screw. Please make sure that the blade is inserted fully into the round blade holder. This will avoid potential damage to the round blade.

Replacement of the Round Blade

Unscrew the round blade holder screws and loosen the blade-fixing screw. Insert the new blade. Place the round blade holder with the inserted blade back onto the pins, fasten the screws for the round blade holder and then tighten the blade-fixing screw. Please make sure that the blade is inserted fully into the round blade holder. This will avoid potential damage to the round blade.

When the Round Blade is dull and has to be rotated

Unscrew the round blade holder screws and then loosen the blade-fixing screw. Rotate the round blade in order to reach the closest unused area. Place the round blade holder with the rotated blade back onto the pins, fasten the screws for the round blade holder and then tighten the blade fixing screw. Please make sure that the blade is inserted fully into the round blade holder. This will avoid potential damage to the round blade.

Inserting a new Spare Blade

Loosen the two spare blade mounting screws, open the blade-fixing screw and remove the blade.

Mount the new blade with the mounting screws, and then tighten the blade-fixing screw.

Modification of the Machine by changing its Bed

(e.g. from bassoon to contra bassoon)

In order to modify the machine by replacing the bed, loosen the two gear mounting screws. The gear unit can then be removed. The brass pusher must be tightly positioned on the gear block. Place a piece of paper into the replacement bed under the brass pusher and fix the gear box on the bed with the two mounting screws. Remove the paper from under the brass pusher and carefully check whether the brass pusher scratches or grinds the gouging bed. If it does, please use two layers of paper during assembly.

Safety Instructions

Please always be careful while using your pregouging machine. The blades used in our machines are very sharp and may cause in juries and other damage. Also, the processed cane can sometimes develop very sharp edges, which can lead to injuries. In order to avoid negative consequences, you should follow the following safety instructions during installation, usage and maintenance of your machine:

The pregouging machine is not a toy. The device is therefore not to be used by persons with limited physical, sensory or mental abilities (including children).

You must secure the machine to the working surface with wood screws or a table clamp. The machines must be lubricated regularly, especially after processing wet cane. (The oil holes are in the gear cover.)

Safety Instructions

Please always be careful while using your Reeds 'n Stuff product. The blades used in our machines, and reed making in general, are very sharp and may cause injuries and other damage.

In order to avoid negative consequences, you should follow the following safety instructions during installation, usage and maintenance of your machine:

Reeds 'n Stuff products are not a toys. They are therefore not to be used by children and persons with limited physical, sensory or mental abilities.

Reeds 'n Stuff products are intended to be used indoors.