-

-

Prior to using the machine, please remove the transport lock screw.

-

-

In order not to lose it, the transport lock can be screwed into the hole provided on top of the tower on the right-hand side.

Figure Machine

Figure Carriage

Transport Lock

Profiling the Reed

Prepare the blank by soaking it in warm water for 3-5 minutes and then gently scraping the bark off the scraping surface of the reed.

Scrape the tip of both sides of the blank reed with a knife and then open the reed by clipping the tip.

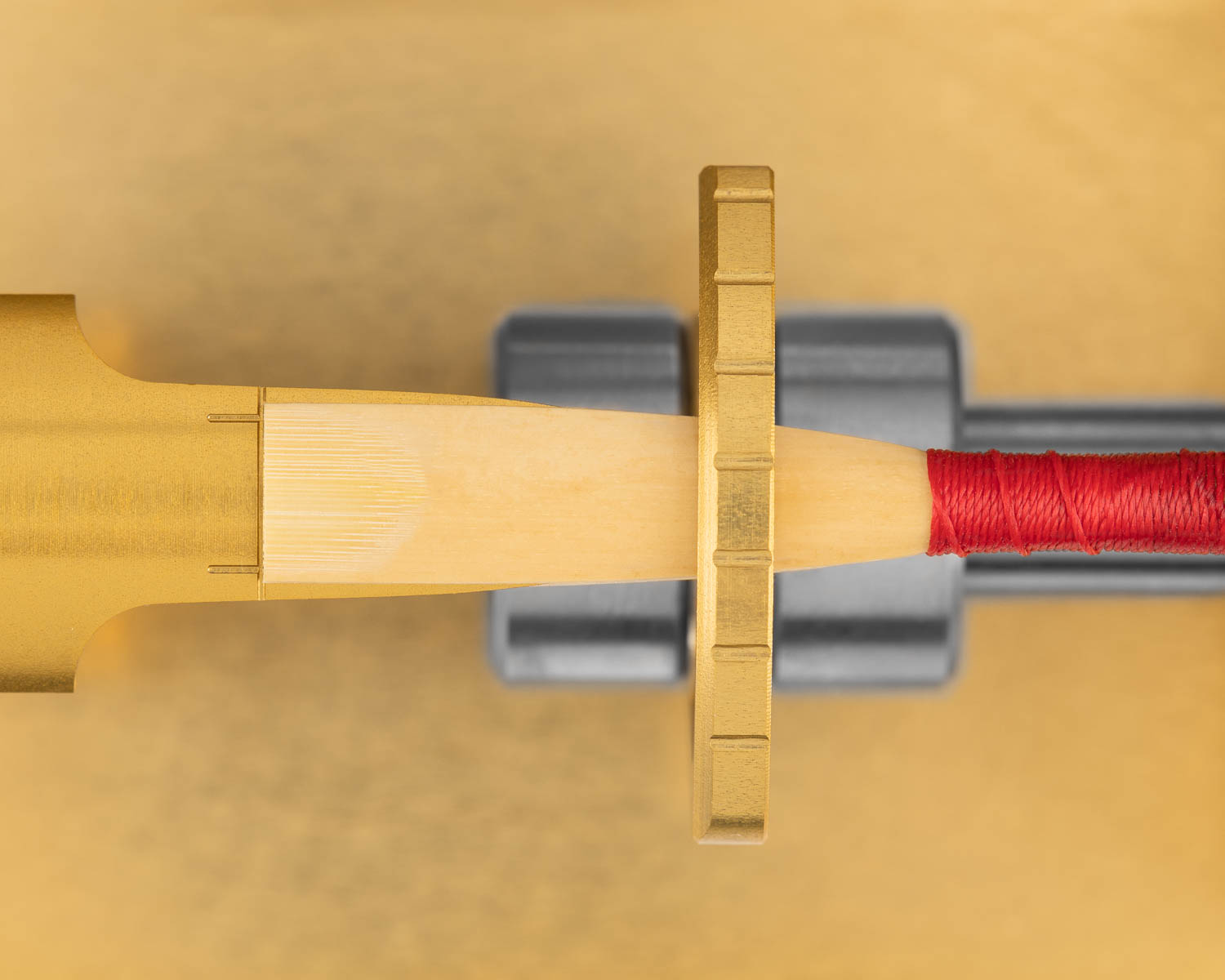

Place the reed on the plaque (9). Push the mandrel (11) snugly into the staple end of the reed. Line up the tip of the reed on the mandrel up to the guide line on the plaque.

The American profiler has 3 guide lines.

- For a longer tip, line up the end of the reed with the first guide line (closest to the template) or even a little over this line

- For a medium length tip, use the middle guide line

- For a shorter tip, use the third guide line

Tighten the mandrel set screw (14) so that it holds the mandrel firmly in place. Rotate the clamp (4) into position.

Begin profiling by moving the carriage (1) with gentle pressure across the cane starting in the tip area. Rotate the handle (10) with your left hand every 3-4 strokes so that you cover the entire scraping surface. Do not rotate the handle during the profiling stroke. Continue profiling in this manner (from one side to the other) until you can remove no further cane from the first blade. Release the clamp and mandrel set screw, and withdraw the mandrel so that the reed is no longer engaged with the plaque. Rotate the mandrel 180 degrees and repeat the process for the other blade.

After the profiling process is completed, remove the reed from the mandrel, clip and adjust the tip as necessary.

Before profiling the entire length, pass over the first 2 mm of the blade with the tip profiler to remove a good amount of the cane at the tip. This will help ensure that as you profile, the corners do not tear out.

Adjusting the Thickness

-

-

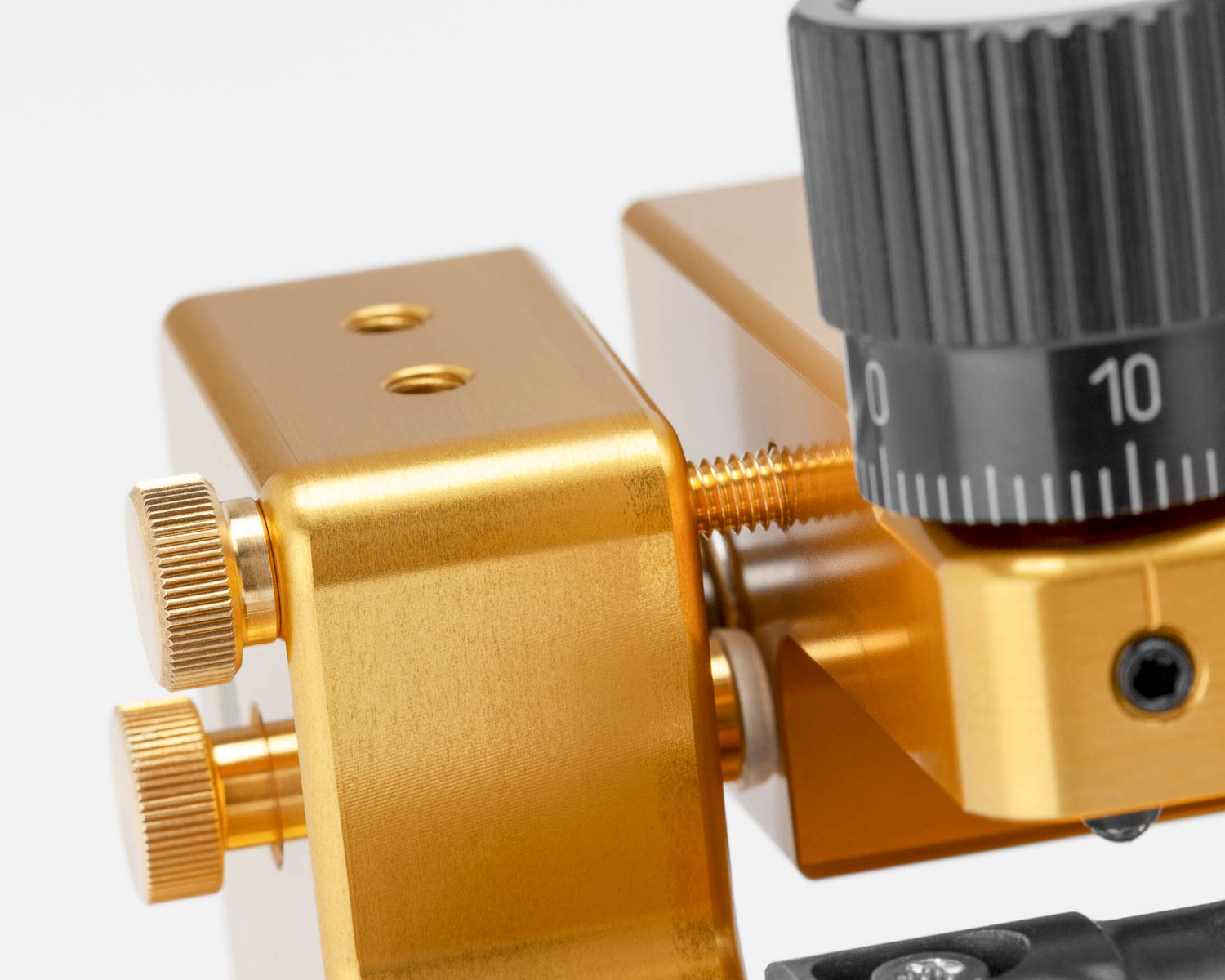

To adjust the overall thickness, first loosen the set screw at the front of the carriage.

Turning the micro-adjuster clockwise will result in thicker reeds, while turning counterclockwise will results in thinner reeds. Each line on the micro-adjuster represents a change in thickness of about 0.01 mm.

After adjusting the thickness, tighten the set screw again. As the tip of the set screw is made of plastic, do not overtighten this screw.

Once you have adjusted the thickness, ensure that the blade does not come into contact with the tongue. This will damage the blade and tongue.

To adjust the thickness of the scrape in the back area, use the tensioning hook to allow the profiler to take more or less cane off of the reed.

-

-

Adding more tension with the clamp will result in a thicker scrape, as the reed will sit lower (further from the blade).

-

-

Releasing some tension from the clamp will allow the profiler to scrape more cane out of the back area, as the reed will sit higher up.

Adjusting the Tip Length

After loosening the set screw for the template (15), the length of the tip can be adjusted by moving the template.

Moving the template (7) closer to the tongue (9) will lengthen the tip area, while moving it away from the tongue will shorten the tip area.

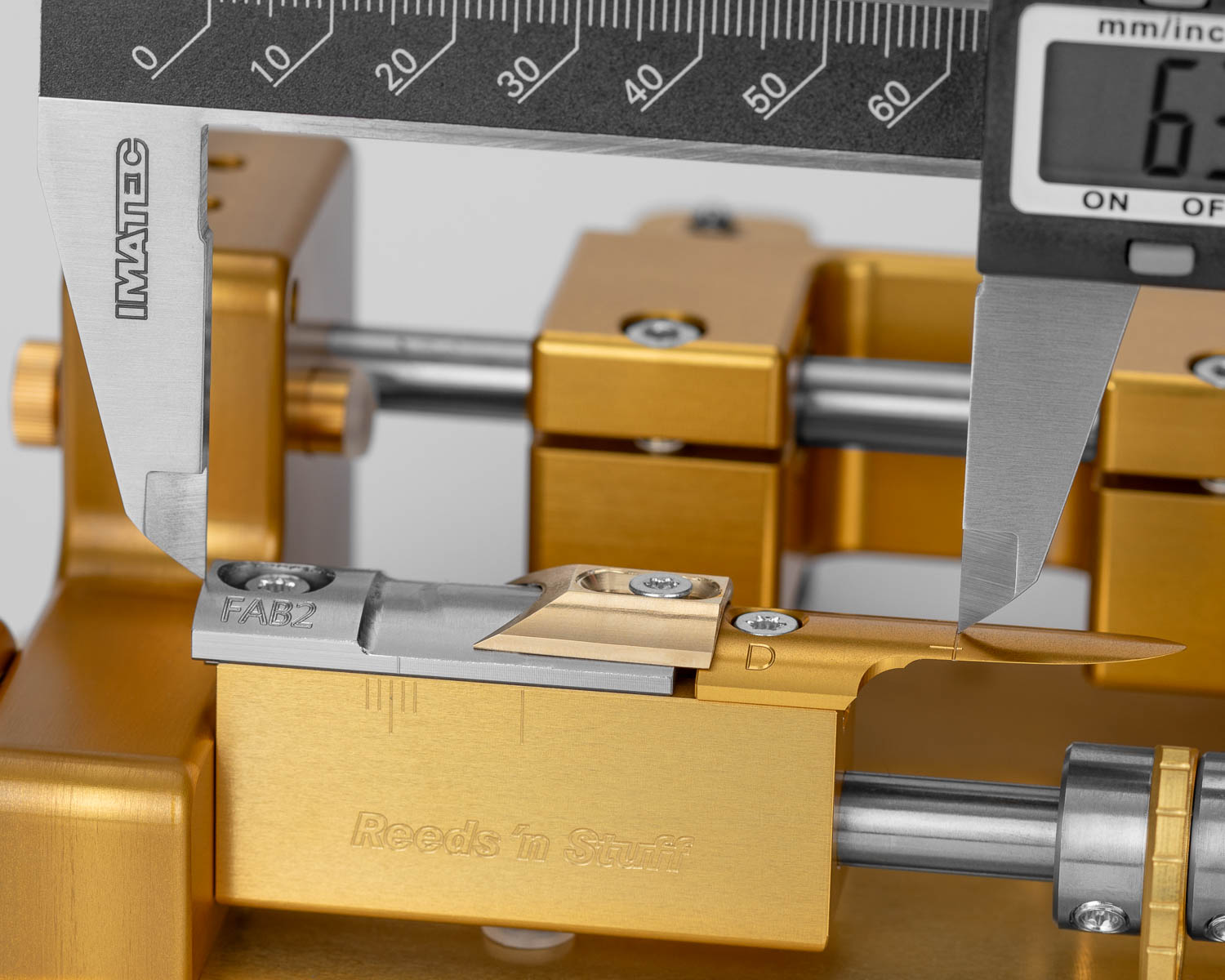

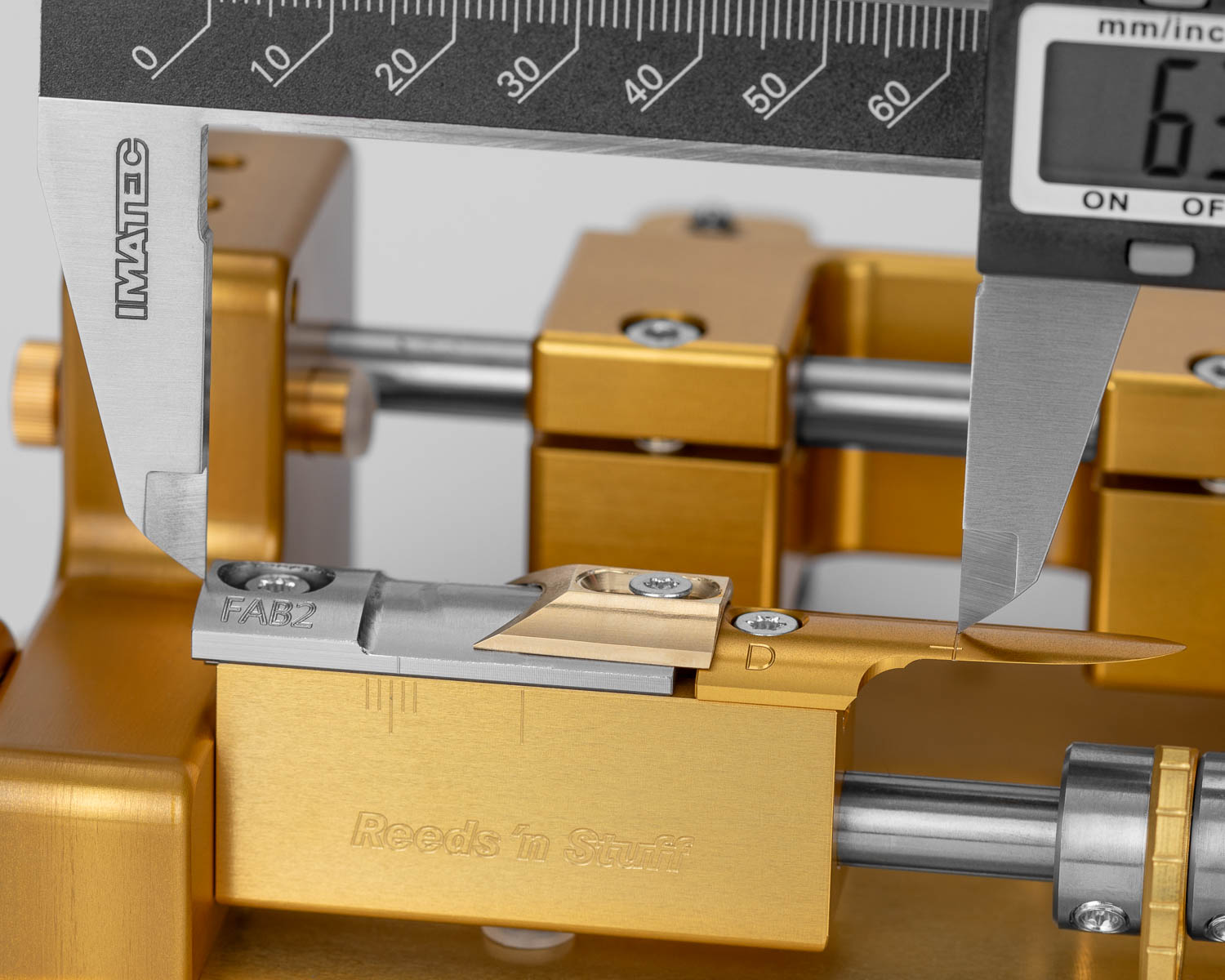

The change in position can be monitored through the scale on the side. For more precision, the position of the template can be measured with a caliper from the far end of the template to the engraved line on the tongue (9).

If the length of the tip is adjusted, the length of the scrape will change accordingly. This needs to be corrected.

Adjusting the Scrape Length

The length of scrape adjustment (8) is fixed by a screw (16). Loosen the screw, set the desired length and then tighten the screw.

If the length of the scrape adjustment is moved in direction of the plaque (9) the length of scrape will get longer.

If the length of the scrape adjustment is moved in direction of the handle (10) the length of scrape will get shorter.

The position of the scrape limiter can be measured with a caliper from the deepest part of the scrape limiter to the engraving line on the tongue.

Adjusting the Carriage Travel

In order to adjust how far the carriage, and therefore the blade, can travel at the tip of the reed, follow these steps:

-

-

Loosen the set screw in order to adjust the travel at the tip of the reed. The adjustment screw with the silicon bumper can now be turned to adjust the stopping point at the tip of the reed.

-

-

The travel of the carriage should be set such that the blade goes just beyond the engraved line on the tongue. Then carefully re-tighten the set screw. The set screw has a plastic cap which can be damaged if over-tightened.

In order to adjust how far back the carriage travels, especially after adjusting the scrape limiter, follow these steps:

-

-

Loosen the set screw in order to adjust the travel at the end of the scrape. The adjustment screw with the silicon bumper and ruler can now be turned to adjust the stopping point at the end of the scrape.

-

-

The travel of the carriage should be set such that the ball bearing for the thickness adjustment stops before entering the opening on top of the scrape limiter. Then carefully re-tighten the set screw. The set screw has a plastic cap which can be damaged if over-tightened.

Changing Templates

After removing the set screw for the template, the template can be removed and replaced.

Once the new template has been attached, and the set screw tightened, please ensure that the blade does not come into contact with the tongue. This could damage the blade and the tongue.

This might require adjusting the overall thickness with the micro-adjuster.

Setting up or reseting a template

The following tables provides the most crucial measurements for setting up the templates on the profiling machine.

Before scraping with a new template, make sure to check the thickness settings so the blade does not come in contact with the tongue.

The length of the tip can be adjusted by moving the template.

-

-

The position of the template (Distance to Line) is measured with a caliper from the far end of the template to the engraved line on the tongue.

-

-

The position of the scrape limiter can be measured with a caliper from the deepest part of the scrape limiter to the engraving line on the tongue.

Machines delivered from the factory are set up with a length of scrape of 10.50 mm for oboe, and 12 mm for English Horn.

For a scrape of 10.50 mm, set the scrape limiter at 34.90 mm to the engraving line on the tongue.

For a scrape of 12 mm, set the scrape limiter at 32.40 mm to the engraving line on the tongue.

Machines delivered from the factory are set up with these measurements and the dial then calibrated to 10. This corresponds to a thickness of 0.10 mm at the tip of the reed (on US-style templates this measurement is taken off-center to account for the spine).

Oboe

| Template |

Distance to Line |

|---|---|

| 17 | 63.20 mm |

| 20 | 63.90 mm |

| 22 | 62.80 mm |

| 24 | 62.80 mm |

| 33 | 63.20 mm |

| 36 | 62.50 mm |

| 60 | 62.90 mm |

| 901 | 62.80 mm |

| ADAM | 63.00 mm |

| ALBI | 63.50 mm |

| ANA | 63.25 mm |

| AO | 63.50 mm |

| AO1 | 63.20 mm |

| CD5 | 63.50 mm |

| CGG | 63.50 mm |

| CR2 | 63.60 mm |

| DNAN | 64.00 mm |

| DW | 63.70 mm |

| FAB2 | 63.00 mm |

| FT | 63.30 mm |

| GREG | 63.20 mm |

| J | 63.10 mm |

| JLC | 62.80 mm |

| KUN | 62.70 mm |

| LORY | 62.90 mm |

| MAU | 62.80 mm |

| MT | 63.20 mm |

| NC | 63.10 mm |

| NCV | 63.10 mm |

| NSD | 63.00 mm |

| WITT | 63.40 mm |

English Horn

| Template |

Distance to Line |

Distance to Scrape Limiter |

|---|---|---|

| CA2 | 63.10 mm | 32,40 mm |

| CA3 | 63.50 mm | 32,40 mm |

| E70 | 63.60 mm | 32,40 mm |

| JC | 62.30 mm | 32,40 mm |

| LOW | 63.40 mm | 32,40 mm |

| MHO | 63.00 mm | 32,40 mm |

| NICO | 62.70 mm | 32,40 mm |

| SPS | 62.70 mm | 32,40 mm |

Oboe & English Horn US

For US templates, place the template all the way to the right, up against the tongue. The scrape limiter is placed as far right as possible.

Viennese Oboe

| Template |

Distance to Line |

Distance to Scrape Limiter |

|---|---|---|

| 22A | 64.38 mm | 33.70 mm |

Historical Oboe

The scrape limiter is placed as far right as possible.

| Template |

Distance to Line |

|---|---|

| BAK | 62.00 mm |

| BAL- | 61.90 mm |

| BPF- | 59.15 mm |

| BTL- | 59.70 mm |

| SHO | 63.00 mm |

| STB | 62.20 mm |

Changing Tongues

To change or replace the tongue, simply remove the set screw (17). Once it has been removed, the tongue (9) can be replaced.

Calibrating the Thickness Adjustment Knob

The thickness adjustment knob (20) can be calibrated, so it shows the exact measurement. Loosen the set screw (28) and turn the scale so it shows the actual measurement.

Replacing and Adjusting the Blade or Blade Holder

Loosening or removing the set screw will enable the blade (or blade holder for the Blade 360) to be replaced or adjusted. Adjusting the blade position works best when the set screw is snug against the blade or blade holder, as this light friction will ensure that the blade or blade holder is not moving too much at once.

After replacing or adjusting the blade or blade holder, re-tighten the set screw firmly so that the blade is securely fastened.

Once the blade or blade holder has been replaced or adjusted, and the set screw tightened, please ensure that the blade does not come into contact with the tongue. This could damage the blade and the tongue.

Adjusting the blade or blade holder is best done with the use of a Blade Adjustment Indicator, as achieving the ideal shaving thickness of 0.03 mm is nearly impossible without the aid of a dial indicator.

Rotate the 360° blade

-

-

To rotate the blade, first loosen the screw on the underside of the blade holder with the attached screwdriver.

-

-

Carefully rotate the blade to the next desired position.

-

-

Hold the blade in place while tightening the screw with the provided screwdriver and you are ready to profile.

Note: be sure not to over-tighten the screw holding the blade. Due to its small size it is possible to damage the screw and/or screwdriver in this manner.

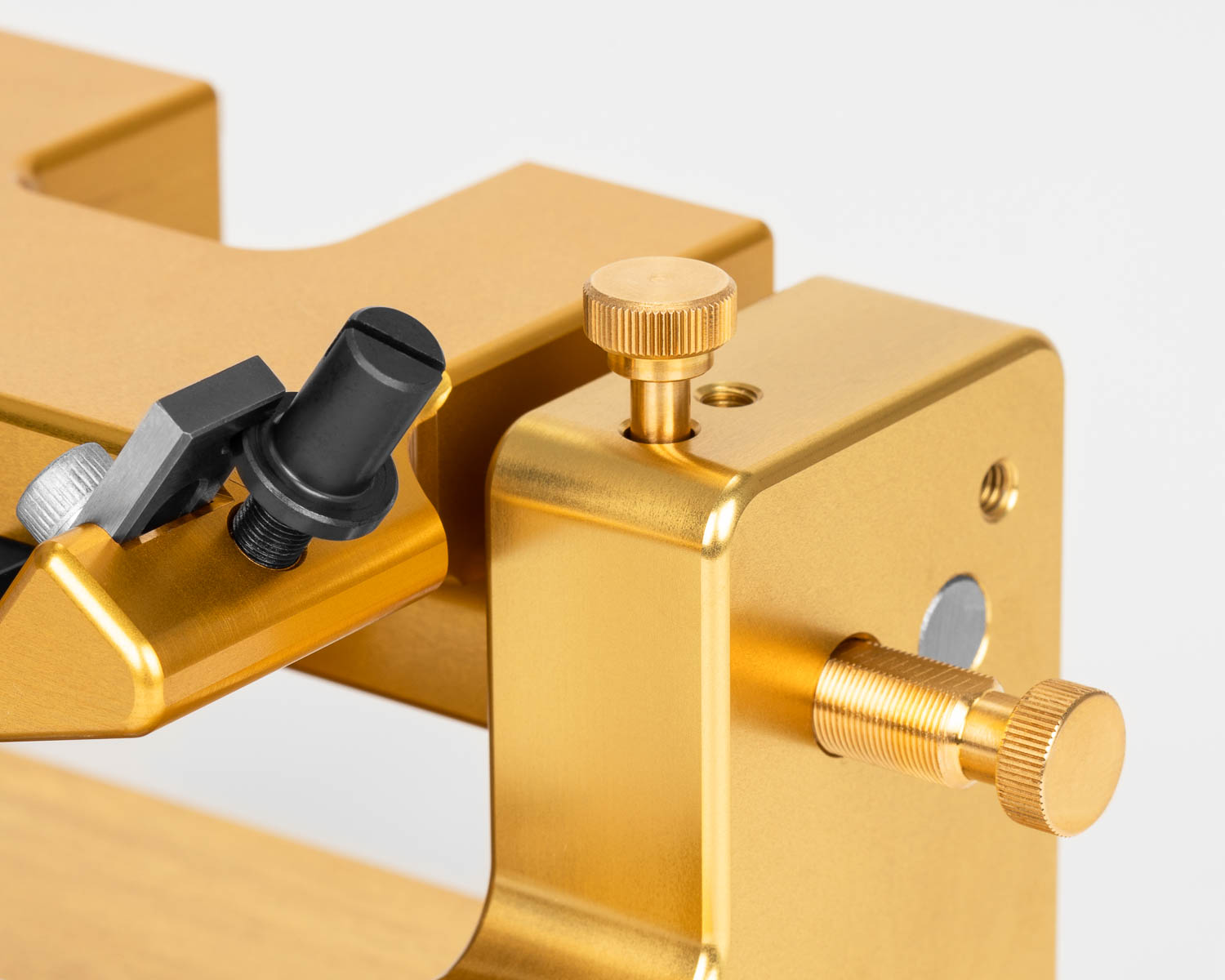

Adjusting the Position of the Clamp

The position of the reed clamp (4) can be adjusted. Loosening the screws (18) on the positioning rings (5) on either side of the clamp allows the clamp and rings to be moved to a desired position. Once this position has been attained, tighten the screws on the positioning rings.

Please ensure that the clamp does not come into contact with the blade, as this can lead to damage.

Safety Instructions

Please always be careful while using your Reeds 'n Stuff product. The blades used in our machines, and reed making in general, are very sharp and may cause injuries and other damage.

In order to avoid negative consequences, you should follow the following safety instructions during installation, usage and maintenance of your machine:

Reeds 'n Stuff products are not a toys. They are therefore not to be used by children and persons with limited physical, sensory or mental abilities.

Reeds 'n Stuff products are intended to be used indoors.