Figure Machine

pending

General Comments

The purpose of flexibility testing cane is to discern differences between pieces of cane and select those pieces which have the greatest potential for making excellent bassoon reeds.

Valid comparisons can only be achieved if the following criteria are met:

- Gouge thickness must be consistent from piece to piece (usually cane from a specific supplier is acceptable). Variations of .002 or .003 in gouge thickness will not have a significant effect on flexibility readings. However, larger variations will affect the results.

- Gouge type (eccentric or concentric) must be the same from piece to piece.

- Cane length must be the same from piece to piece.

- Cane width must be the same from piece to piece. Establish a desired width, and trim pieces that exceed this width for consistency.

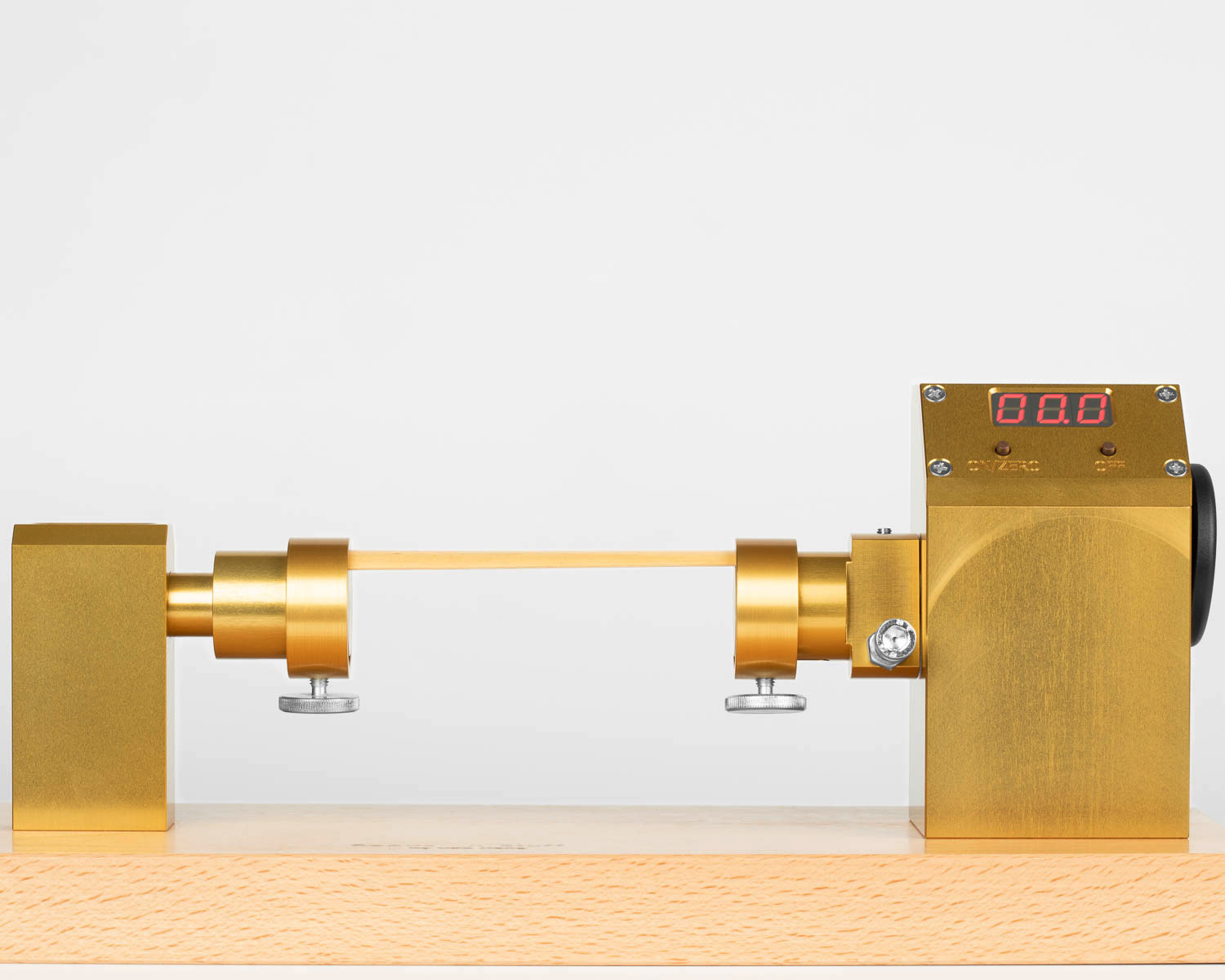

Using the Flexter

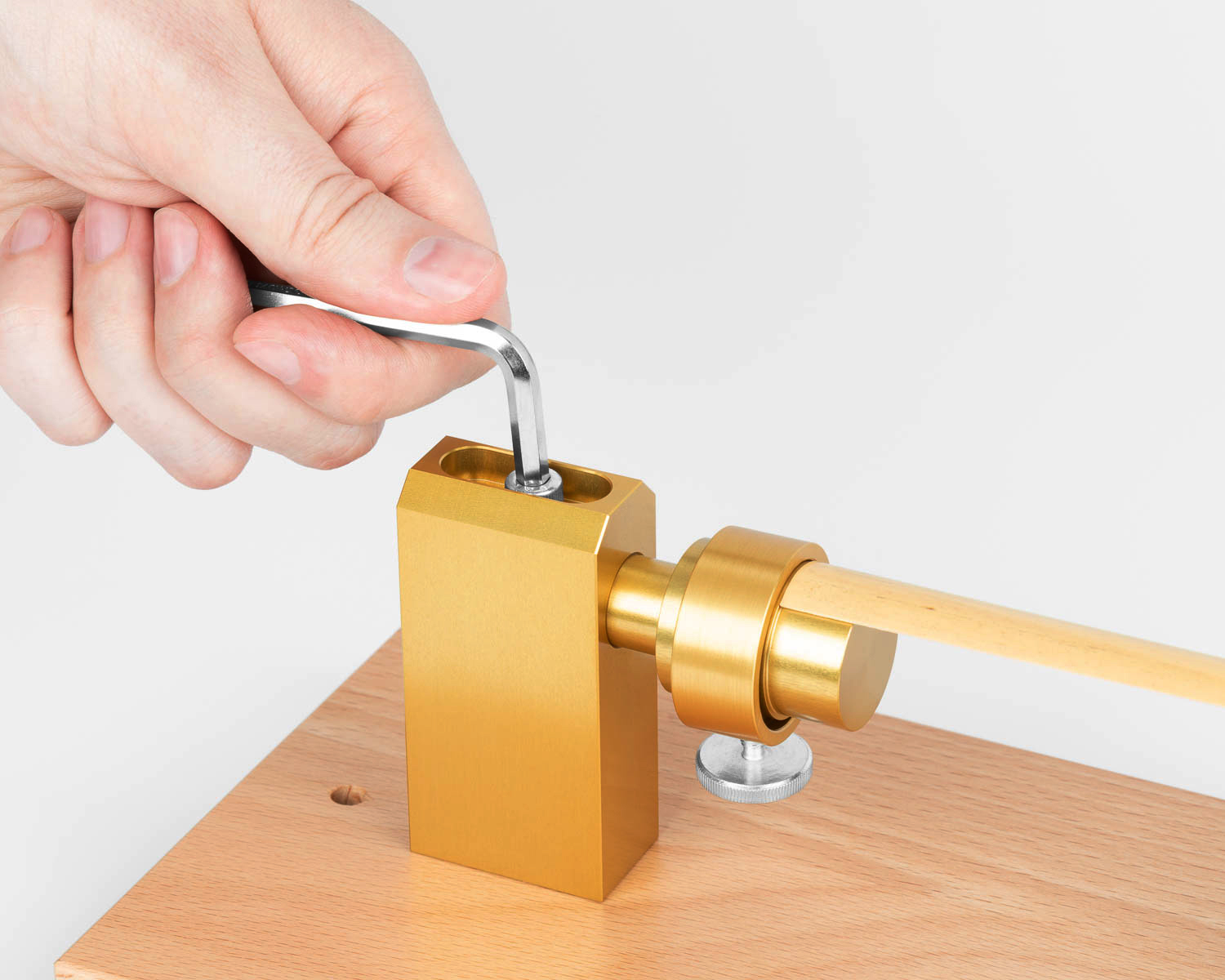

Loosen the clamps just enough to slide them onto the large diameter of the locators. Adjust the Flexter tailstock (Image 1) to fit your cane length with the cane placed on the smaller diameter. To do this, loosen the lock screw and adjust the tailstock position until there is a small amount of clearance between the end of the cane and the larger diameter of the tailstock.

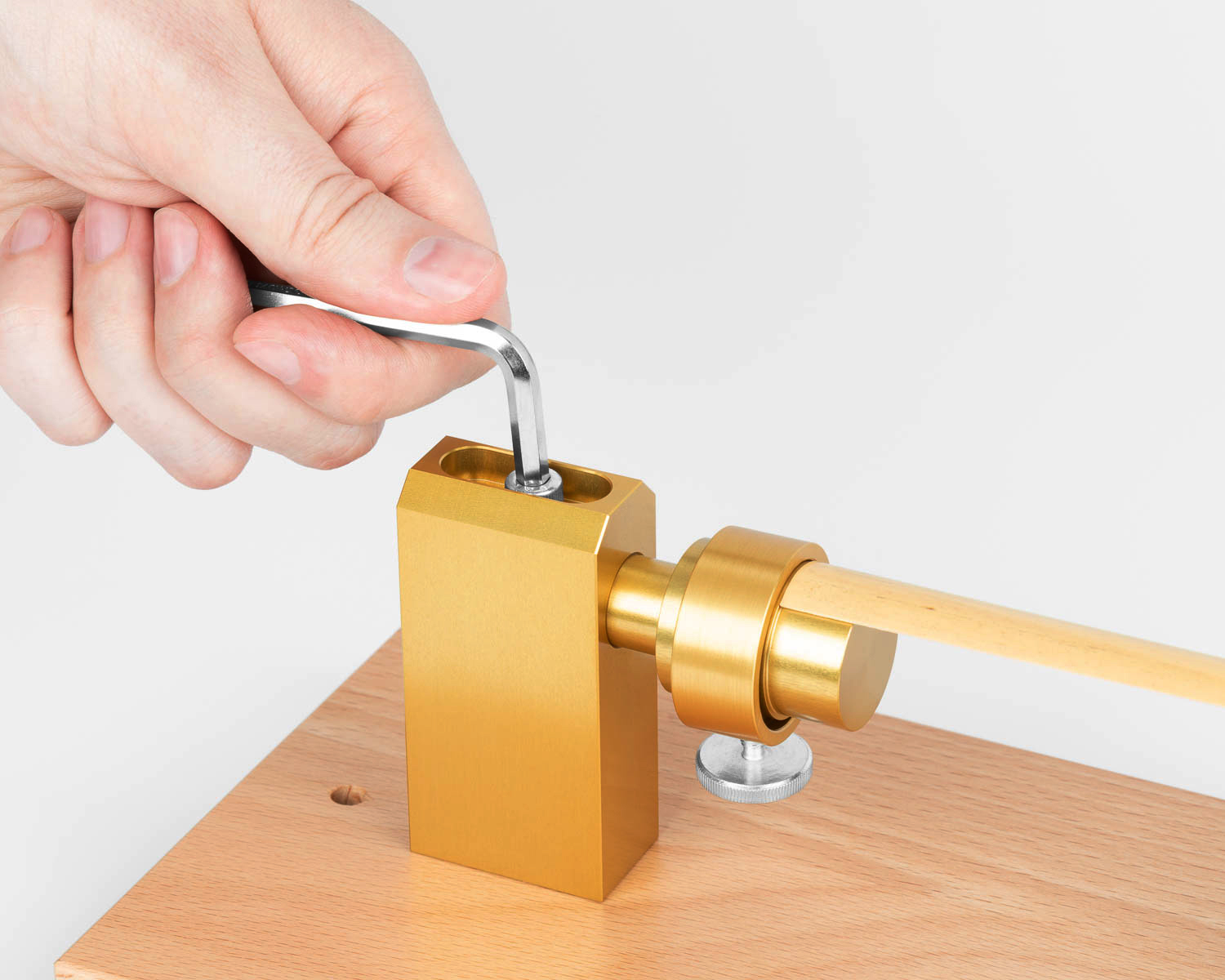

Place the piece of cane to be tested on the small diameters between the two horizontal centering lines. It is important that the cane be located accurately between the lines (Image 2.) Slide the clamps over the cane at each end and tighten securely.

Press the left hand button to turn the Flexter on. Press the left hand button again to ‘zero out’ the initial reading.

Place the weight on the actuating shaft.

In 3 to 5 seconds the cane flexibility reading in degrees will appear.

Remove the weight from the actuating shaft, unclamp the cane from the Flexter, and write the flexibility number on the cane for future reference.

Repeat the process by clamping the next piece of cane, pressing the zero button, applying the weight, and after 3 to 5 seconds reading the flexibility in degrees.

Inventor's Research

Download and read Mr. Poe's detailed article recently printed in the IDRS Journal in the Media section below. Diagrams, pictures and all the results of inventors research are included.